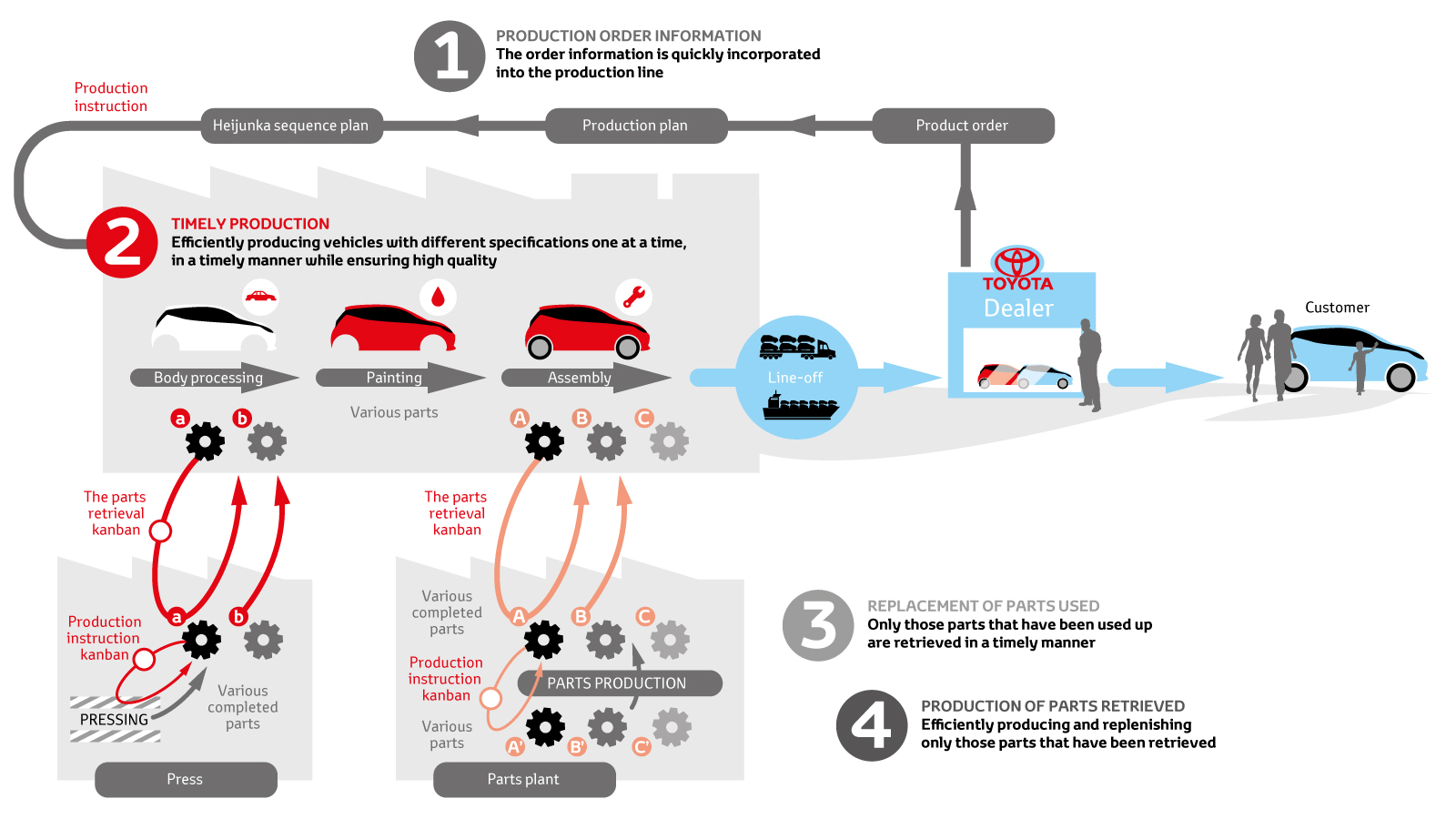

Inventory management systems help you avoid overbuying products that don’t sell. Inventory management can also help you keep inventory costs low—which is important since high storage fees, shipping fees, and manufacturing fees can all eat into your profit margins. Let’s continue with the example mentioned above, where Company A ordered six pieces of a certain good. If the producing company only has orders from Company A, the Just in Time system is advantageous for them. They’ve successfully ordered enough raw materials to produce the goods for Company A, and that is the only order they have for those goods.

How the JIT Strategy Boosts Profitability

Using the lean methodology to identify the 8 types of waste can be done using a Value Stream Map to create a visual of the flow of materials and information throughout the business. Of course, JIT inventory systems fall apart without prompt, reliable item production and shipping. But once you get it down, JIT systems can enhance the efficiency and profitability of your business. The second possible problem may arise if there is a sudden, unexpected surge in market demand for the company’s products.

Key Takeaways

For example, if a supplier delivers goods that are not up to standard, they may have to be scrapped. Conventional manufacturers adopt a system where they “push” their products, disregarding actual demand. Each department receives daily orders for the final assembly of the required parts. This approach often leads to long changeover times and the production of large batches. We have found in buying materials that it is not worthwhile to buy for other than immediate needs.

Just in Time (JIT) Method

Companies that follow the just-in-time inventory model will be able to reduce the number of items in their warehouses or eliminate warehouses altogether. The JIT inventory system is popular with small businesses and major corporations alike because it enhances cash flow and reduces the capital needed to run the business. Retailers, restaurants, on-demand publishing, tech manufacturing, and automobile manufacturing are examples of industries that have benefited from just-in-time inventory. JIT inventory management is a valuable production strategy that can help businesses stay competitive in today’s fast-paced and constantly evolving marketplace. JIT inventory management requires a high degree of discipline and adherence to strict production schedules. This can be challenging if employees are not fully trained on JIT principles and practices, or if there is resistance to change.

Step 2: Plan the JIT Strategy

- The lack of parts being supplied caused Toyota, a company that relied on them, to have to halt production for several weeks, ultimately costing them over $1 billion in revenue.

- The potential for increased waste is another disadvantage of JIT inventory management.

- JIT inventory management provides several benefits to businesses, including cost savings, improved quality, increased productivity, faster response times, and enhanced customer satisfaction.

- Cassie is a former deputy editor who collaborated with teams around the world while living in the beautiful hills of Kentucky.

Businesses must remain vigilant, tracking performance indicators closely, and be willing to evolve their strategies to meet production demands precisely. The payoff of JIT implementation is a leaner, more responsive, and cost-effective operation that aligns closely with customer needs and market fluctuations. The JIT inventory method helps businesses keep enough inventory on hand to fulfill customer orders, while also keeping inventory levels as low as possible. This allows you to enjoy significant cost savings on inventory storage (since you have fewer items to store), but it has a couple of other financial benefits. If a supplier fails to deliver goods on time, it can lead to a stockout, which can have a negative impact on customer service and sales. To mitigate this risk, JIT businesses must have strong relationships with their suppliers and develop contingency plans for dealing with disruptions in the supply chain.

JIT Inventory Methodology

As the season draws to a close and demand wanes, shelves are cleared to make room for the next season’s items. JIT inventory management requires significant investment in training, process improvement, and technology. This can be challenging for small or medium-sized businesses that may not have the resources to implement JIT inventory management fully. JIT inventory management requires efficient transportation and logistics to ensure that products are delivered on time.

Processing smaller batches allowed the manufacturers to reduce financial risk, while slowing generating sustainable levels of working capital. Labor expenses are also reduced since the number of man-hours needed to fulfill orders is likely lower than would be required for full-time production. On-demand production means fewer items sitting on shelves depreciating in value if sales take a downturn, and the risk of losing money if a product becomes obsolete is virtually eliminated.

Next, you will need to rework the layout of the business to Optimize Flow this means arranging machines and workstations to ensure a smooth flow of materials to minimize transport and waiting times. Overall, inventory management is an excellent strategy for any business that sells physical goods. Most importantly, though, inventory management makes your life easier in general. It can help you organize your warehouse, 10 characteristics of financial statements its types features and functions track inventory movement across multiple locations, and even integrate with your other business solutions (like your point-of-sale or accounting software). The goal would then be to time your production rates and forecast demand so you receive your replenishment order just in time to avoid a stockout. Following this pattern on an ongoing basis ensures you don’t have to store more components than you actually need.

Learn how to cut fulfillment costs, increase efficiency, and automate manual tasks. Below is a break down of subject weightings in the FMVA® financial analyst program. As you can see there is a heavy focus on financial modeling, finance, Excel, business valuation, budgeting/forecasting, PowerPoint presentations, accounting and business strategy. Originated by Toyota, the JIT inventory/production system has since become popular with other major manufacturing companies such as Harley-Davidson Motorcycles and Dell Computers. Disruptions in the supply chain can easily result in an inability to produce goods, as was the case in 1997 after a fire at a Japanese auto-parts supplier forced them to temporarily halt production.

Despite Ford’s proclamations, however, it was not the Ford Motor Company that provided Toyota representatives with a JIT model in action. When the representatives toured plants in the United States in 1956, Ford had not yet fully implemented the JIT model. Instead, it was at Piggly Wiggly, the first self-service grocery chain in the U.S., where they discovered the model on which to base their own JIT system. You can use technology such as Electronic Data Interchange (EDI) to share information in real-time with suppliers to provide better coordination and communication and minimize supplier issues for the business. Following this, you should develop a roadmap and outline the steps and timeline for implementation, including any capital investments required for changes in equipment or infrastructure.